Do you know how to calculate Safety Stock?

Content

Additionally, safety stock can help ease tensions and better relationships with your suppliers and customers. If you have positive numbers in your variance category, they represent the number of days over the expected times. If you have negative numbers in the category, then the delivery arrived earlier than the expected time.

- Implementing measures to gather more accurate data and use better tools to analyze it can improve demand forecasting, positioning your business to be able to fulfill every order.

- Divide that total by 30 and you will come up with an average daily sales volume.

- So while anticipation inventory is geared towards predictable events, safety stock is there in case of a totally unexpected occurrence.

- Before we dig into explaining how to use a safety stock formula, it’s useful to define what the term safety stock actually means.

- To account for delivery delays or periods of strong demand, you must stock 470 additional items.

For that reason, fixed safety stock works best for retailers who experience consistent customer demand and very few supply chain disruptions. Although we’ve provided a way to perform basic calculations, safety stock isn’t limited to a single formula. Rather, there are multiple methods you can choose from depending on your needs or business structure.

Standard Safety Stock Formulas

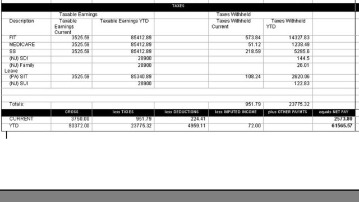

We have explained how to calculate the other figures in the previous methods. Out of the 10 deliveries you received for the year, the average lead time was 35 days with a max lead time of 40 days. This method is commonly used but can be difficult if you have a particularly long lead time. Essentially you are aiming to calculate the average max units you need at any one time. Remember, there are more variables that go into the ordering process than just safety stock.

Different formulas help inventory managers determine how much safety stock they need and calculate some critical variables. Running low on stock is an inevitability, but it doesn’t have to disrupt business. Learning how to calculate safety stock and keeping adequate amounts on hand ensures that the supply chain runs smoothly despite stocking delays and temporary outages.

How to choose the right formula for your Safety Stock?

It can help lower the likelihood of supply shortages and reduce inefficiency, client dissatisfaction, lost sales, and decreased revenues. Because we know that it will only continue https://kelleysbookkeeping.com/ for six days, you can use 2,707 units as your starting point for further orders. Place another order once your inventory reaches this point, reducing the likelihood of a stockout.

- Use the formula that fits your store’s circumstances so you can always offer the products your customers need without overstocking your inventory.

- Time series analysis projects future demand based on past data, while causal analysis establishes a causal relationship between demand and one or more independent variables.

- If your lead time variation is small, you will likely have a much lower safety stock because you know your supply will be fairly consistent.

- Consider the quality and volume of your data before selecting the best formula for your safety stock.

- Anticipatory stock is inventory a business acquires in anticipation of a spike in demand or forecasted trend.

- This kind of stock benefits retailers by ensuring they can meet customer demand (even as that demand is surging).

This is relatively simple to understand and a really useful calculation to know. On the other hand, a product like desk fans is much more difficult to forecast. Generally you might sell more in the summer months, but how can you plan for a heatwave when demand is unexpectedly high? To cover an uncertainty like this you require much more safety stock of desk fans than you do for razor blades. Safety stock is simply extra inventory held by a retailer or a manufacturer in case demand increases unexpectedly. This means it’s additional stock above the desired inventory level that you would usually hold for day-to-day operations.

Average – max safety stock formula

For manufacturers and companies that assemble products using different components, lead time is a critical factor to determine minimum inventory and safety stock requirements. Using a safety stock formula helps you to take a data-driven approach to inventory management, maximizing sales and ultimately profits. Since different products will have varying daily demand and lead times, you’d use this formula on a per-product basis. Forecasting demand is one of the areas where you can do a lot of math.

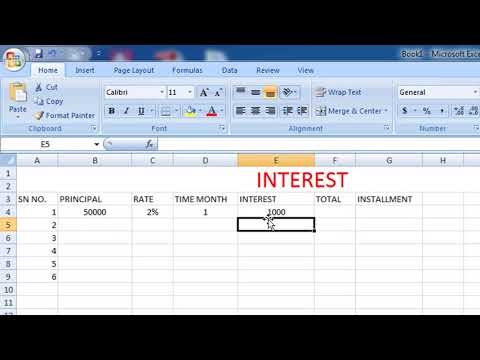

The basic safety stock formula is a good place to start if you’re unsure about the more advanced methods. Those basic calculations can give you a ballpark idea about how much safety stock you might need — especially when specific variables about your inventory and lead times are unknown. This formula assumes that you know the maximum and average values of your daily usage and lead time.

However, this isn’t recommended as it can cause issues with stock outs causing customer frustration and lost sales. We recommend setting safety stock at 50 percent of the lead-time demand initially. If you regularly see overstock, try lowering your safety stock to percent of lead-time demand.

- A lower score means you’ll have higher chances of running out of stock.

- The calculation is easy, provided reliable purchase and sales order histories are available.

- However, if some of your items experience strong seasonality, opt for a specific period, to the weeks or months in the same period of the previous year.

- That data should be easily accessible if you’re using inventory management software.

- To do this, multiply the average daily sales by a specific time period, like 14 days, for example.

- So, it is relatively simple to see how this reorder point calculation can be bought into action once your safety stock levels are ascertained.

So, as an example if you set a service level of 50% it means that you have a 50/50 chance of selling more or less than the ‘average’ month of sales. This makes having safety stock important for efficient supply chain management. It is a failsafe measure and shelters your business against disruptions. Businesses cannot afford to lose customers or disappoint them if a product goes out of stock. These customers may replace your product with something else available on the market and never return.

Cycle stock is the inventory expected to be purchased by consumers, while safety stock is like the margin of error you can dip into when things go wrong. At times, fluctuations in demand are predictable — like when you run a flash sale or another type of promotional campaign. But at other times, businesses experience an influx in sales due to a market shortage or a sudden change in the economic landscape.

- Without it, you’ll fall behind your competitors the moment something unexpected comes up.

- These are all values which can be calculated, but you need to pick a period of time over which to calculate them.

- Manage your orders and get real-time insights through our shipping software.

- To estimate the number we’ll use during this time, we multiple the average daily demand by the average lead time.

Time-based calculation allows you to calculate safety stock levels over a specific time period based on future demand forecasts. Although it depends on the product sold, most retail businesses try to maintain normal service levels between 90% and 95%. You must utilize a standard distribution chart to convert your intended service level into a number that can be used in the safety stock calculation. Concerning the service level you intend to achieve, this will assist you in determining your service factor. It can also be very costly, as your company loses sales and consumers when there are stockouts.

Matching lead time and forecast period

While demand is not always easy to predict, knowing the right amount of safety stock at the right time is helpful for all businesses. Lead time demand (LTD) is simply the total product demand over the lead time – a simple multiplication of lead time (L) by demand (R). Average daily usage refers to the average number of units you sell per How To Calculate Safety Stock? Safety Stock Formula And Calculation day. The inventory strategy at the company for the manufacturing parts with the high cost and low volume is the MRP system. Based on this, a safety stock strategy is necessary for this particular category of parts. Suppliers’ support cannot always be reliable, and hence safety stock comes into action for backing up this variability.